I-Gubber Gomers

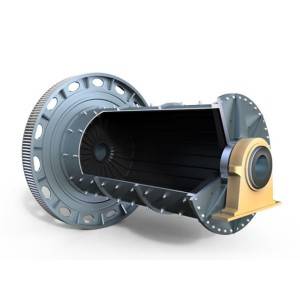

I-liner yerabha ithathe indawo yokutshintsha i-liner yentsimbi ye-manganese. Inokuthwala ifuthe lokuxhathisa. Isivuno sesekethe yakho yokugaya ixhomekeke kakhulu kwi-mugraber yakho yerabha. Khetha ngasekunene komthengisi wakho werabha ngononophelo uya kuqinisekisa ukuba inkqubo yakho yokugaya ibaleka ngamandla okuqala kunye nokufumaneka.

I-Liner Liners ihlala ilungele ukugaya okumanzi, iqondo lobushushu aliphezulu kwe-80 dagrees yomsebenzi oqhelekileyo, kodwa iqondo lokunganyangeki elisileyo, ukuchasana kweoyile kunye nenye indawo ekhethekileyo, kufuneka ichazwe kwangaphambili ngokwahlukeneyo Ifomula yoyilo eyenziweyo, ukongeza, inkqubo yokugcina kufuneka ibekwe kwindawo engasebenziyo, inqwenela iingubo zerabha ukuthintela ukuvezwa ngaphandle kunye nemvula.

Ngokweenjongo, ii-liner zerabha zisetyenziswe kwi: Ag, i-SAG, ibhola, i-rod kunye ne-rod kunye ne-futch mills.

Ngokutsho kobume, yahlulwe ngohlobo oluphuthiweyo, uhlobo lwegridi kunye nohlobo lwe-bin-bin oluninzi, olunokuhlangabezana neemfuno zenqanaba lokugaya kwinqanaba elinye kunye nenqanaba elinamanqanaba amabini.

Singazenza ngokwezifiso zonke iintlobo zexabiso eliphezulu kunye ne-raber ephindwe kabini yokunganyangeki ngokweemfuno zomthengi ngamnye.

Iimbonakalo

1. Ukusetyenziswa kwamandla asezantsi

2. Ukunganyangeki okuphezulu

3. Ulondolozo olusezantsi

4. Ukunganyangeki kwempembelelo

5. Ingxolo ephantsi

6. Kulula ukufaka

I-7. Ukunganyangeki

I-8. Ukonga iibhola zentsimbi

Imivalo yokuphakamisa

Iibhanti zokuphelisa ziyafumaneka kuluhlu lobubanzi, ubude kunye neeprofayili zerabha. Imivalo yokuphelisa ibandakanya ukufakelwa kwentsimbi zenzelwe ukubonelela ngefuthe eliphezulu kunye nokuxhathisa i-arasion.

Ukugcwalisa kunye neqela lekona

Ukuzalisa kunye necandelo leekona zenzelwe ukutshixa iipleyiti zentloko kunye ne-grate plike kwisikhundla kwaye uyeke ukubaleka kwezinto ezibonakalayo kwiimbombo.

③ Iipleyiti zentloko

Iipleyiti zentloko yerabha ziyafumaneka kwiindlela ezahlukeneyo zokulwa i-abrasion. Iipleyiti zentloko zenzelwe ukuqhuba lula ufakelo kunye nokuphatha

④ I-Grate Plates

Ubutyebi be-Grace-Crace Plates ziyafumaneka kwii-mills ezinkulu. Ipropathi ye-elastic yerabha ivumela i-slots ezincinci kunemithi yentsimbi apho kuphelisa iingxaki ezingaboniyo. Ifumaneka kuluhlu lwesayizi.

I-Cones iCones kunye ne-Trunnion I-Liners

I-cones yeziko ingenziwa kumacandelo okulula kufakelo.

I-Trunnion kunye ne-lill yomlomo

I-Lindenion liner zenziwa kwisiseko sentsimbi esinentambo, esiyibhuleyini esilingeneyo. I-liners yentsimbi yentsimbi yentsimbi ixhaswe irabha isetyenziswa kwi-Trionnion enkulu kunye ne-bell.

⑥ I-Pulp Pulters

⑦ I-Inrip Pulp Puspters

I-Rubber Lien Puep Puaters yenzelwe ukubonelela ngokukhutshwa ngokuchanekileyo kwepulp ngokulandelelana kwebhotile ukunciphisa iibhotile.

Iipleyiti ze-shell

Ubungqingqwa beepleyiti ze-shell buyahluka ukuze kwandise amandla e-Mill kunye / okanye ubomi bomlilo. Ububanzi yenzelwe ukhuseleko kwimivalo yokufundiswa.

Isalathiso sepropathi yomzimba

| Intsebenzo | Iyunithi | Isalathiso |

| Ukophula amandla | Mpa≥ | 18 |

| I-Elongition kwikhefu | % ≥ | I-420 |

| I-300% yoxinzelelo oluqhubekayo | Mpa≥ | 12 |

| Ubunzima | I-Shore A (Degree) | I-64-68 |

| I-Akron abrashion | cm³ / 1.61km | I-0,1 |

| Ifuthe | % ≥ | 45 |

| Ukukrazula isiphoso esisisigxina | % ≥ | 10 |

| Umlinganiso werabha kunye nentsimbi | Kn / m | 6 |

Yonke imihla yeyokwesiqhelo kunye nokubonisana nomzi-mveliso ukuze ufumane i-fection ekhethekileyo.