Inkqubo yokuhlolwa kwerabha

Imithombo yeendaba oyivaliweyo yinxalenye ebalulekileyo yesixhobo sezinto zokuhlola. Xa isikrini sokuhamba sishukuma, ngokusebenzisa imilo eyahlukeneyo kunye nobungakanani bejometri kunye nesenzo samandla angaphandle, izixhobo ezingaphezulu ziya kwahlukaniswa kwaye zifezekise injongo yokuhlela. Zonke iintlobo zepropathi yezinto ezibonakalayo, isakhiwo esahlukileyo kunye nezixhobo zephaneli yokukhangela okanye uxinzelelo kunye neeparamitha ezahlukeneyo zinefuthe elithile kwi-screen ekwakhethekileyo, ireyithingi kunye nobomi. Izinto ezahlukileyo, iindawo ezahlukeneyo, kufuneka zikhethe iimveliso zosasazo ezahlukeneyo ukufezekisa iziphumo ezingcono.

Kuxhomekeka kwizixhobo ezahlukeneyo, iimfuno kunye nemeko, imithombo yeendaba yokukhangela inokwahlulwa ngothotho oluphantsi

I-1.modum Series

2.Ingcelele

I-3.Panel Series

Unxibelelwano kunye nezixhobo lwahlulwe ngokubanzi: Unxibelelwano lukaMosaic, unxibelelwano lwe-bolt, uqhagamshelo lwe-bolt

Izicelo zemigodi

1. I-ore ye-ore

I-Tep- heap leaach

I-3.High Cacu Gace

4.Imigca yokukhutshelwa kwezikrini

5. Imijikelezo yeMithombo yeendaba

Uvavanyo lwe-6.Control-Ukususwa okuhle

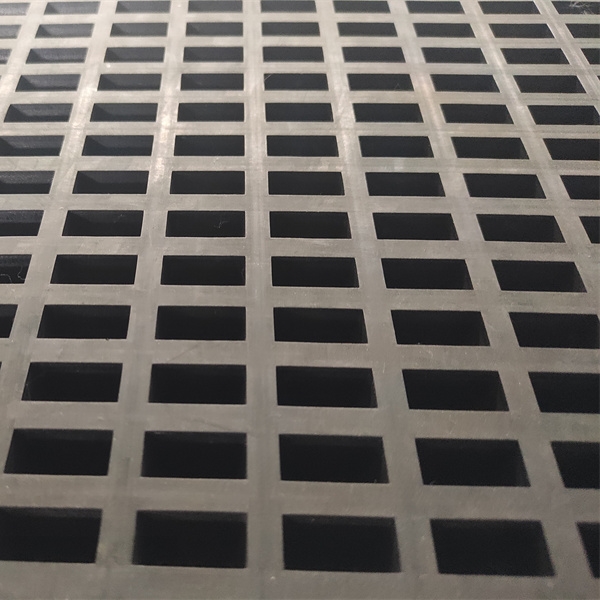

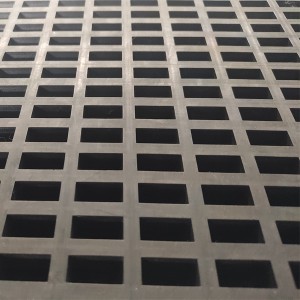

Inkqubo ye-Rubber System yahlukile koyilo lwe-rubber, ukongeza kokusetyenziswa kwenkqubo yerabha yerabha yerabha (le nkqubo icacisa indlela ye-punching yemveli kwinkqubo yomonakalo wemveliso), imveliso ayinasiphako esiphezulu, kodwa kwakhona Unokuvula iyunifomu. Indawo yendawo ayisoze iphule. Xa kuthelekiswa nezikrini ze-wire, ezinayo indawo esezantsi yokuvula kwimilinganiselo encinci. I-TATS yethu yerabha yenziwa zizixhobo ezilinganayo nezinganyangekiyo, zilungile njengeedesika ezigqibeleleyo kwiibhokisi ezinkulu zekrinte okanye njengecandelo lempembelelo. Ezi zikrini ziyafumaneka kuluhlu lwezikwere okanye izihlunu ezinamafutha ukuba zilungele zonke iimfuno zomgangatho. Inzuzo ye-mats ye-screen i-screen lithuba elinde kakhulu lokuphila kwaye linciphise amanqanaba engxolo. Isikrini se-teraber screen sihle kakhulu kwi-Coarse kwizicelo zovavanyo oluhle. Ukusetyenziswa kwerabha kuya kunciphisa ingxolo, ukunciphisa ibhloko kwaye unike izakhono ezizodwa. I-screen rubber ye-screen mat ifakwe kwi-2 yeengqengqelo zomgangatho weprimiyamu enxibe irabha yokunganyangeki ngentambo yokuqiniswa phakathi kweendawo. Ubungakanani bezemali kunye nemeko yokusebenza nayo iyafumaneka ngesicelo.

I-Rubber Panel Screen Series

I-Rubber Screen Senvest

Ipharamitha yokusebenza kweemveliso ezihlombe zerabha

| Ipropathi | Iiyunithi | Ixabiso |

| Ubunzima | Shore a | 63 |

| Tensile strength | Mpa | I-19 ± 10 |

| Uqhagamshelane | % | I-660 ± 10 |

| Amandla eendaba | N / mm | 313 |

| Ilahleko ye-Abrasion | % | 37 |

| Amaqondo obushushu asebenzayo | -30 ℃ ukuya + 60 ℃ | |

| Umbala | Mnyama |

Iimbonakalo

I-1.High yovavanyo olusebenzayo

2.Nguqulunqwa kwescreen

3.1ng Ubomi benkonzo

4.Uchasayo

5.Coriyasion Ukuxhathisa

Ukuchasana