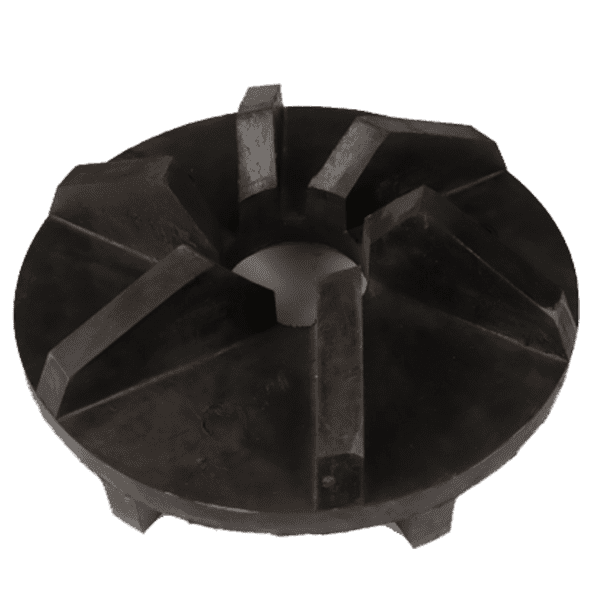

Irabha yerabha kunye ne-rotor yomatshini wokudada

Isitetori kunye ne-rotor, ikakhulu isetyenziswa kumatshini wokudla kwe-XJK Series, uthotho, i-SF, i-BGF ithongile, i-KYF yothotho, i-KYF yothotho, uthotho, uthotho lwe-XJF, i-BJF, uthotho, uthotho lwe-XJF, e-BJF, e-BJF, uthotho, uthotho lwe-XJF, e-BJF, e-BJF.

Isitetori kunye ne-rotor, ikakhulu isetyenziswa kumatshini wokudla kwe-XJK Series, uthotho, i-SF, i-BGF ithongile, i-KYF yothotho, i-KYF yothotho, uthotho, uthotho lwe-XJF, i-BJF, uthotho, uthotho lwe-XJF, e-BJF, e-BJF, uthotho, uthotho lwe-XJF, e-BJF, e-BJF.

I-rotor kunye ne-statoring yomatshini ovuthuzayo iqashelwe ikakhulu yi-skeleton yensimbi kwaye inxibe irabha-irabha. Ukufakwa kwentsimbi ye-skeleton kwenziwa ngokunqunyulwa kwelangatye kwaye emva koko ihlelwe ngokuchanekileyo phantsi kwemigangatho yenkqubo engqongqo. Amandla kunye nokulinganisa ukulungelelana kwe-Skeleton kuqinisekisiwe kukufumanisa ukulinganisa ngenteyanqa elinamandla. I-rotor yerabha kunye ne-stactor yomgangatho womatshini wokugungxula wawunxibe ngerabha yokunganyangekiyo kwaye ivulwe kwiqondo lokushisa eliphezulu.

Inkampani yethu ineetoni ezingama-3600 zeplate enkulu ye-pulcanizer kwaye ikwazi ukuvelisa i-rotor kunye ne-stator yamatshini wokudakumba ukusuka kwi-300 mm. Ukuba imfuno ibaluleke kakhulu, sinokuyenza ngokwezifiso ngokweemfuno zabathengi.

Iipropathi zezinto zerabha

| Into | Iyunithi | Isalathiso |

| Amandla e-thensle ≥ | 17 | |

| I-Acid (isiseko) I-InfoSO₄ (20% Simahla) 18 ℃ x24h | 0.8 | |

| I-elongication kwikhefu ≥ | % | I-450 |

| Ubunzima | Ubunzima obukhuni a | I-55 ± 5 |

| I-Boir eshushu ye-Aulding Augadid | 0.75 | |

| Ilahleko ye-Abrasion | cm³ / 1.61km | 0.7 |

| Izinyithi kunye ne-amber Adsion≥ | Mpa | 2.5 |

| Ukuphelisa isiphoso esisisigxina | % | 30 |

| I-oyile i-oyile i-20 # ioyile 100 ℃ x24h | % | ± 10 ~ 5 |

Iimbonakalo

1. Ukunganyangeki kwe-abrasion

2. Ukunganyangeki

3. Ukunganyangeki kwempembelelo

4. Ukuzinza kwamachiza

5. Ubomi obude bobomi

Nxiba isisombululo

1.Ukusebenzisa iipatheni zokunxiba kunye nenqanaba kwindawo ebaluleke kakhulu kwaye uqiniseke ukuba ubonakalise umqondiso ngenkqubo yokusebenza.

2.by usebenzisa irabha yerabha okanye i-politithane ye-polytorthane kwindawo apho kufuneka uninzi kuwo wonke icandelo. Kwaye oku kuyakwenza ubomi ngokusebenza.

3.Ukufumana uvavanyo lobungcali kunye nesondlo xa ulisebenzisa ngabathengi bethu. Kunye nokufumana ingxelo yohlaziyo rhoqo kwinkqubo yokusebenza, eya kuthi ibonelele kwaye yonyuse ukubakho kwesityalo.

I-Skeeel skeleton

1.Umxholo wobuqhetseba usebenzisa i-3CR12 yeentsimbi zentsimbi, kwimeko ye-rust kunye ne-bolt ekutshixweni.

Inkqubo yokuphendula iphendula kwimigangatho ye-ISO ngabasebenzi abanamava kwaye igcina ibhalansi kwaye ichaneke xa ihlalwa.

3.Ukusebenza komsebenzi kuxhomekeke kwimfuno yomthengi okanye ufumane isisombululo kwiqela lethu letekhnoloji.